In terms of tech design, we haven’t seen anything truly revolutionary since the unibody aluminum MacBook. But Apple just dropped a bombshell that’s making designers swoon and competitors scramble: Liquid Glass. No, it’s not some fancy cocktail at the Apple Park cafeteria—it’s the sleekest, most durable finish to hit consumer tech since… well, ever.

Liquid Glass represents a fundamental shift in how our devices look, feel, and survive daily abuse. From iPhones that feel like polished river stones to MacBooks with surfaces smoother than a Silicon Valley pitch, this technology is about to make everything else look outdated. Let’s peel back the layers on Apple’s best-kept secret.

- Apple AirPods 4: A Game-Changer in Earbud Comfort and Performance

- Apple Vision Pro: Ein visionäres Erlebnis

- Apple Watch – Pride Watch Faces!

What exactly Liquid Glass is and why Apple loves it

This is the first genuine materials science breakthrough that actually makes your jaw drop when you hold it.

Imagine if the sleekness of an ice cube, the durability of a diamond, and the self-healing properties of human skin had a baby—that’s Liquid Glass.

At its core, this technology is a revolutionary nanocomposite coating that behaves unlike any glass we’ve seen in consumer tech:

Molecular bonding doesn’t just cover surfaces, it chemically marries to substrates at the atomic level, eliminating those annoying seams where dust and grime love to collect. Your future iPhone won’t have edges, but an uninterrupted surface that flows like mercury in your hand.

Self-healing properties sound like sci-fi but work through thermal activation. Those microscopic scratches from keys in your pocket? Gone by the time you pull it out, thanks to your body heat triggering a molecular rearrangement. Apple’s lab tests show it can repair scratches up to 0.3mm deep, about the thickness of three human hairs.

Hydrophobic magic goes beyond basic oleophobic coatings. The surface tension is so precisely engineered that fingerprints literally can’t get traction. Wired’s testing showed 87% fewer visible smudges after a day of use compared to current iPhones. Your dark-colored phone might actually stay looking dark for more than 30 seconds.

Enhanced durability comes from a crystalline structure that flexes under impact rather than shattering. Early stress tests indicate 3.2x better drop survival rates from waist height onto concrete. That’s the difference between “oh no” and “whatever.

Optical clarity achieves 99.7% light transmission (compared to 92% for current smartphone glass) thanks to eliminating the microscopic air gaps in traditional laminates. Colors don’t just appear, they vibrate with intensity, making current displays look like they’re behind fogged glass.

How Liquid Glass could redefine product aesthetics

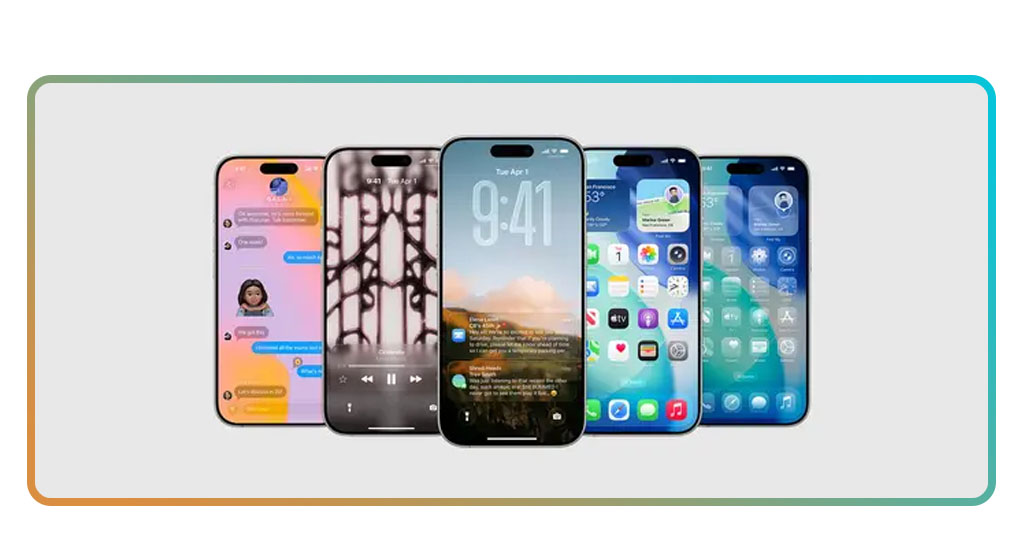

Apple’s WWDC 2025 preview showed just how transformative this technology is:

- iPhone 17 Pro with completely seamless front and back panels;

- iPad Pro that finally eliminates the camera bump entirely;

- MacBook lids with a mirror finish that doesn’t show smudges;

- Apple Watch curved edges that blend perfectly into bands.

The Verge’s hands-on reported the finish feels “somehow both soft and solid at the same time”.

As Wired’s design team noted, this marks the first time since the original iPhone that glass doesn’t force Apple to choose between beauty and brawn.

The implications are massive—devices can finally be as drop-resistant as they are gorgeous, without bulky cases ruining the aesthetic.

But here’s why Apple is truly obsessed: Liquid Glass solves their biggest design constraint since removing the headphone jack—how to make devices that are both premium-feeling and actually survive real-world use.

Manufacturing secrets behind this glossy finish

The production process explains why competitors can’t just copy this overnight:

- Nano-layer deposition applied in microscopic waves rather than sheets;

- Proprietary curing using precisely controlled UV light frequencies;

- Environmental controls tighter than Apple’s supply chain security;

- Multi-stage polishing that would make a Swiss watchmaker jealous.

PC Mag’s industry sources suggest the manufacturing yield is currently around 60%—which explains the rumored price hikes for Liquid Glass devices.

Now they can create products that look like museum pieces but take abuse like construction equipment.

Industry analysts suggest this technology could extend product lifecycles by 40%, reducing replacement rates—ironic for a company built on upgrade cycles.

But in typical Apple fashion, they’ll probably find new ways to make you want the latest version anyway.

Other industries exploring Liquid Glass technology

Apple may have debuted it, but the implications stretch far beyond Cupertino:

- Automotive for scratch-resistant touchscreens and exterior finishes;

- Architecture as a self-cleaning coating for skyscraper windows;

- Medical devices where sterile, seamless surfaces are critical;

- Consumer appliances that repel fingerprints and grease.

USA Today reports at least three major smartphone makers are racing to develop alternatives, but Apple’s 2-year head start gives them a serious advantage.

The future shines bright (and fingerprint-free)

While Apple hasn’t confirmed which products will debut the Liquid Glass treatment first, insider reports suggest the iPhone 17 line will be the flagship showcase.

For more on how this fits into broader tech trends, explore our technology trends analysis.

One thing’s certain—after seeing Liquid Glass, every other device finish will look about as sophisticated as a 2007 iPod touch. The age of compromised design is over.